CS8674020B1A---RVSD

CS8674020B1A---RVSD

Search Results for: push pin

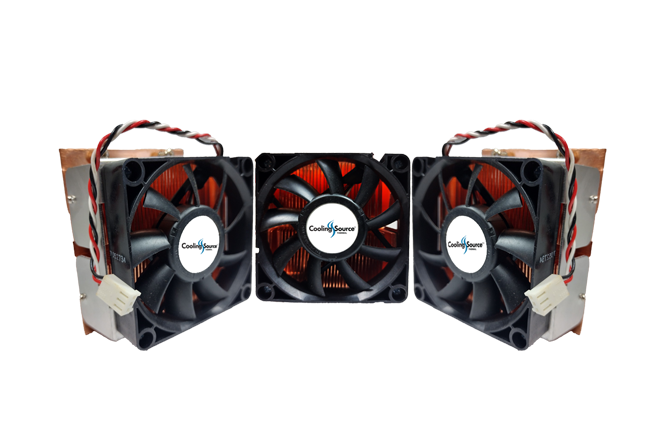

Push Pin Heatsink

Push Pin Heatsink

DIM: 45 x 45 x 10mm

Push Pin Heatsink

DIM: 45 x 45 x 20mm

Push Pin Heatsink

DIM: 45 x 45 x 20mm

BGA Heat sinks

Standard Heatsinks

What are heat pipes?

What are Heat Pipes and What Makes Them Beneficial for Cooling Electronics?

Heat pipes move10 W/cm2 to 20 KW/cm2 of heat at high speed to enhance your heatsink performance.

Los Alamos National Laboratory tested the first heat pipe in 1963. Engineers design heat pipes for laptop computers, military, telecom, medical devices, and LED applications, among other things. Figure 1 depicts the working of a heat pipe:

Heat pipes move10 W/cm2 to 20 KW/cm2 of heat at high speed to enhance your heatsink performance.

The evaporator, adiabatic, and condenser are the three portions of a heat pipe.

The evaporator, adiabatic, and condenser are the three portions of a heat pipe. Wick travels inside the tube with a few drops of purified water. When the fluid inside the evaporator portion (L) is exposed to a heat source, it vaporizes, and the pressure in that area rises. The higher pressure allows the vapor to travel quickly toward the heat pipe’s condenser section (L ). By transferring the latent heat of vaporization to the condenser, the vapor in the condenser section loses heat to the inbuilt heat sink and is transformed back to liquid. The liquid is then pushed back to the evaporator by capillary action in the wick. The temperature differential in the center segment of the heat pipe (La), the adiabatic region, is relatively modest.

The wick’s capillary pressure must be greater than the pressure differential between the vapor and the liquid at the evaporator for the capillary force to push the vapor. As a result, there is less wick pumping and less heat transfer. Thus, the heat pipe determines the quantity of heat transmission reduction in question.

The following are the components of a typical heat pipe:

- a metal pipe Aluminum, copper, or stainless steel can all be used. However, to avoid chemical reactions like oxidation, it must be compatible with the working fluid.

- Working fluidly To date, a variety of fluids have been used. Methane, water, ammonia, and sodium are among them. The operational temperature range also influences fluid selection.

Wick The wick structure is available in a variety of shapes and materials. The profiles of popular wick types are shown in Figure 3: axial groove, fine fiber, screen mesh, and sintering. Each wick has its personality. The axial groove, for example, has strong conductivity, low heat resistance, and poor flow against gravity. On the other hand, a sintering wick has a good flow in the opposite direction of gravity but has high heat resistance. The are several reasons the maximum heat transfer rate from a heat pipe is limited.

The following are the categories:

- Limit of the capillaries The pumping movement of the wick restricts heat transfer.

- Maximum sonic volume When the vapor exceeds the speed of sound, the only way to enhance the heat transfer rate is to raise the evaporator temperature.

- High heat fluxes can cause boiling point restriction. Dry out.

- Maximum entrainment The return of the liquid to the condense can be hampered by high-speed vapor.

The effective thermal conductivity of a heat pipe

is substantially higher than that of a suitable metal conductor like copper. Both pipes started at a temperature of 20°C. In around 25 seconds, the heat pipe temperature approaches the water temperature; however, the copper rod temperature only reaches 30°C after 200 seconds. Cooling Source can secure the Heatpipe in place with solder or epoxy material. Consequently, it may reduce the heat pipe’s effective thermal conductivity due to the additional thermal resistances introduced by the bonding. A rule of thumb regarding a heat pip’s effective thermal conductivity

There are a variety of heat pipe designs available.

The most typical is round or flat. Heat move easy from point A to point B with a round heatpipe. CSI’s design Heat pipes assemblies for electronic components in closed space, such as in a laptop. Cooling Source engineers design Heatpipe assemblies to move the heat of the source to a cooler area of the system. Figure 6 depicts some of the most popular circular heat pipes on the market.

The notion of flat heat pipes (vapor chambers) is the same as that of round heat pipes. However, when the heat source is significantly smaller than the heat sink base, a flat heat pipe can be embedded in the base or attached to the base to distribute the heat more equally on the heat sink base.

A vapor chamber may help reduce spreading resistance, but it may not perform as well as a plate built of a high conductor, such as diamond. The thickness of the base plate is a deciding element. Figure 9 demonstrates the spreading resistance of several materials on an 80 x 80 x 5 mm base plate with a 10 x 10 mm heat source. The spreading resistance of the vapor chamber is better than copper but lower than diamond. The diamond’s cost, on the other hand, may not justify its use.

In the field of thermal management, heat pipes play a critical function. They will continue to be a vital feature of some new thermal systems, with predicted lifespans of 129,000-260,000 hours (as claimed by their manufacturers). Cooling Source tests every Heat pipe when we receive them. After the heatsink assembly is complete, we test once again the heat pipes to ensure good performance.