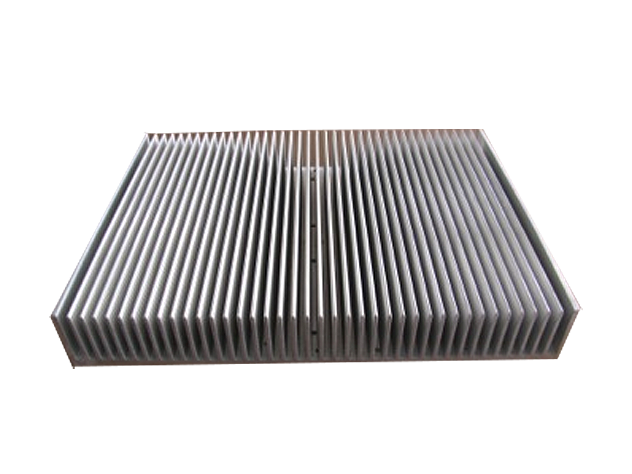

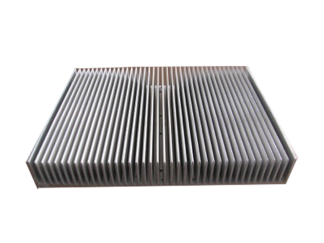

Description

| AXL | B | C | D | E | NFI (number of fins per inch) | Part Number |

|---|---|---|---|---|---|---|

| 9″x9″ | 0.315″ | 0.5″ | 0.10″ | 0.100″ | 5 | CS500-435-F-00 |

Standard Extrusion Made In The USA

Standard Extrusion, this type of heatsink is available in either standardized versions or custom-built to your specifications. An aluminum block is pushed (extruded) through a die to create a straight or cross-cut finished heatsink during the manufacturing process. Also, we can manufacture complex fins and per your specifications. As a result, we can provide a wide range of convection cooling solutions suitable for high-power components.

Extruded aluminum heatsinks can be a great solution when you want to keep your tooling costs low and still achieve a low per piece cost, along with little or no secondary machining.

CSI manufactures Extruded Heatsinks in a wide variety of shapes. Consequently, each type fulfills a different need. So, if you are not sure which is the right choice for your company, our experts can show you the benefits of each process to help you determine which aluminum heat sink extrusion will work best for your needs.

Advantages of Extruded Aluminum Heatsinks include:

Our standard parts don’t require a tooling fee. They are manufacture from a standard bar of aluminum using a machine specially designed to make this type of parts.

Characteristics:

High fin density can provide improve cooling performance

Lighter weight than copper

More efficient than stamped heat sinks

Lower cost than CNC machining

You can customize designs

Flatbacks useful for components such as power modules

Unique shapes geared for use in electronic power assemblies

These complex fin profiles allow more excellent heat dissipation through the increased surface area while eliminating the cost and time associated with machining an equivalent shape from block aluminum. A simple call or e-mail will put you in touch with one of our experts.